Use of non-destructive testing methods in a new one-specimen testing strategy for estimating fatigue data

The aim of the present research project is to exploit the potential of non-destructive testing methods, the digitalisation of measurement technology and signal processing to combine them with a novel one-specimen testing strategy in order to achieve a clear gain in information regarding fatigue behaviour while simultaneously reducing the effort and cost of testing. This not only provides a considerable advantage over the conventional determination of S,N data, but also over established short-term methods, if a large number of material effects on a single specimen can be separated by means of data analysis and this can be used as a basis for a fatigue life calculation.

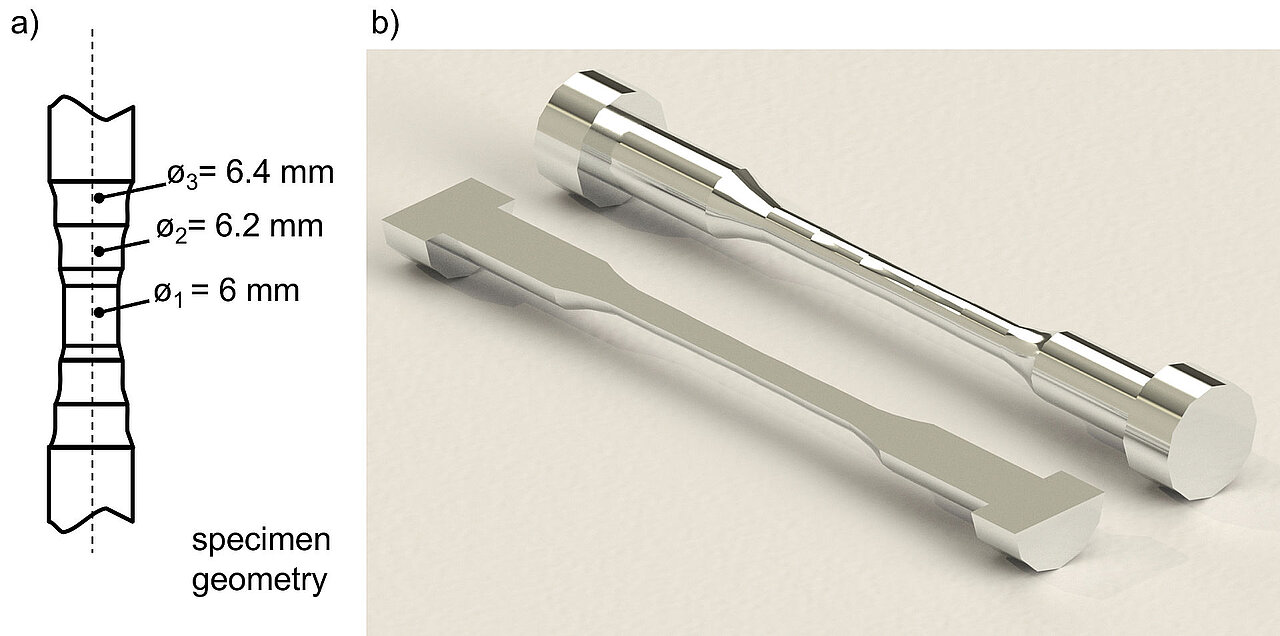

In the new fatigue life calculation method SteBLife (Stepped Bar Fatigue Life Evaluation), a stepped fatigue specimen with several test sections is used and the local material reactions are recorded via assigned NDT measurement variables. Prior investigations have already shown very promising results for specimens made from C45E. Here, the material reaction was recorded with an infrared camera, which is to be deepened in the context of this research project by the additional use of thermocouples and extended by magnetic measuring methods.Contrary to the conventional approach, the specimens for this are not to be magnetized with electric or permanent magnets, but by means of an applied constant/alternating current or voltage in order to build up a specimen's own microstructure-dependent magnetic field.

Vizepräsident für Forschung und Transfer, Studiengangsleitung "Maschinenbau, Bachelor", Fachbereichsrat AING

- +49 631 3724-2389peter.starke(at)hs-kl(dot)de

- Campus Kaiserslautern

- Room H1-2010.1

The measurement signals obtained in this way will be analyzed with regard to their progressions and occurring patterns, whereby in particular the simulation of the measurement signals using commercial simulation software such as COMSOL can make a significant contribution to understanding and interpretation. The experimental investigations, simulations and signal analyses will be performed on unalloyed and low-alloyed C-steels (C20E, C45E and 42CrMo4) in the normalized and commercially available quenched and tempered conditions.

Keywords: lifetime calculation, short-term method, non-destructive testing, NDT, magnetics, signal analysis