"MibaLeb" microstructure-based fatigue life calculation

The objective of the joint project is the development of a procedure for the evaluation of the remaining service life of metallic components aged during operation in nuclear power plants. It is taken into account that the local material properties of components can change significantly due to the loads occurring during operation. This applies in particular if corrosive influences are in addition to the mechanical and thermal loads.

The central tasks are the development and provision of non-destructive measuring and testing methods, which are used in particular for the characterisation of the unloaded initial condition as well as for the evaluation of the fatigue behaviour in process-oriented constant amplitude tests.

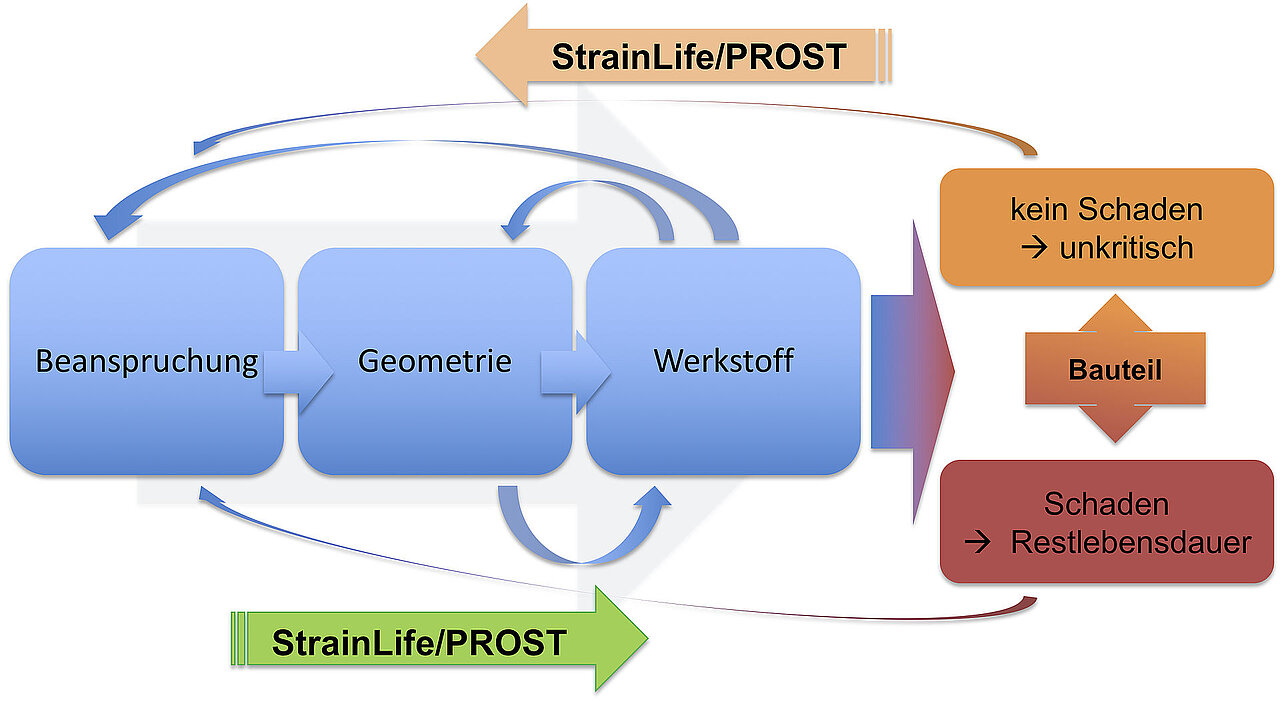

In addition, the StrainLife method will be promoted with regard to the specific boundary conditions in nuclear applications and the measurement and testing methods used will be upgraded for the use in the StrainLife method, thus creating a basis for the extension of existing service life calculation methods such as PROST.

Vizepräsident für Forschung und Transfer, Studiengangsleitung "Maschinenbau, Bachelor", Fachbereichsrat AING

- +49 631 3724-2389peter.starke(at)hs-kl(dot)de

- Campus Kaiserslautern

- Room H1-2010.1

In the case of a pressurized pipeline filled with superheated steam or supercooled water, it must be assumed after a certain operating time that the local scatter of the material properties specific to the loads continuously increases.

The effects of such influences are currently covered in general terms by safety factors in the design of the components due to the lack of further information. An increase in qualified information can delay the replacement of affected components considerably while maintaining the same level of safety. This is where the joint project should make a decisive contribution.