Evaluation of the frequency influence on the fatigue behaviour of unalloyed steels

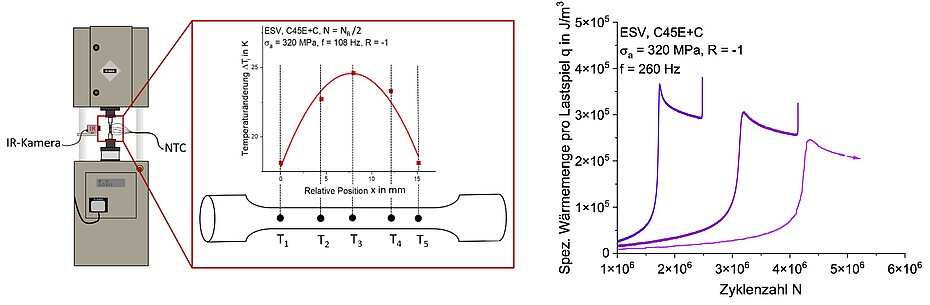

Fatigue life prediction methods (LPV) developed at WWHK in recent years have so far been limited to the transition between LCF (Low Cycle Fatigue) and HCF (High Cycle Fatigue) and to the HCF regime. This has recently led to controversial discussions regarding the utilisation of the potential of LPV, which is why comprehensive investigations are being carried out within the scope of this research project. The fact that the procedures and methods have not yet been extended to the VHCF (Very High Cycle Fatigue) regime is due to the fact that the necessary testing infrastructure was not available at the WWHK. Due to the approval of the large-scale equipment proposal INST 252/21-1 (468976436), a resonance testing system was procured and put into operation, which makes it possible to also achieve numbers of cycles in the VHCF regime in a technically justifiable time frame.

Two factors in particular must be considered here. Relevant damage mechanisms can change from the HCF to the VHCF regime. For example, the crack initiation points shift into the volume in the field of defects, such as inclusions and precipitates, especially in the case of high-strength conditions. In the case of ductile materials, damage development can also be detected below the critical threshold value for the activation of persistent sliding bands, which can be attributed in particular to the high number of cycles and the associated accumulation processes. For this reason, it is necessary to check which of the measurement techniques used so far can also be used for the range of high numbers of cycles. The deformation rate or test frequency has a significant influence on the damage development per cycle. Higher test frequencies generally lead to an extension of the service life. It is essential that the relationship between frequency and damage contribution and the resulting fatigue life can be quantified and thus made usable for LPV. The aim is therefore to develop LPV for the use in the VHCF range and to implement influences with regard to deformation rate and stress-related mechanisms in mathematical approaches and to validate the prediction quality through experiments.