Servo-hydraulic vibration testing machines

- 2 x Shimadzu EHF-L 20 kN (static 25 kN, cyclic 20 kN, up to 50 Hz)

- 1 x Shimadzu EHF-U 50 kN (static 55 kN, cyclic 50 kN, up to 30 Hz)

- 1 x Schenck PC160N (static 160 kN, cyclic 140 kN, up to 10 Hz, modernisation 2020)

Instrumentierung

- Various extensometers for RT and HT (Shimadzu Dynastrain, various Sander Messtechnik)

- Various infrared camera (Micro-Epsilon TIM450/400, Infratec ImageIR® 8300)

- Measuring systems for thermocouples and thermistors (National Instruments, Keysight)

- Uni- and bipolar current sources from Toellner/Kepco for electrical resistance measurement

- Barkhausen noise measurement systems (QASS Optimizer µMagnetic, Stresstech Rollscan)

- Various magnetic field sensors (self-made)

- Eddy Current (Rohmann Elostest M3)

- Videoextensometer (LIMESS Messtechnik)

- Various 2-D DIC systems (LIMESS Messtechnik)

Ambient conditions

- Induction furnace up to 1000 °C (iew TTH3)

- 2- and 3-zone chamber furnace up to 1200 °C (Severn Thermal Solution)

- Corrosion measuring cell (self-made)

Electromagnetic machines

- Russenberger Mikrotron 20 kN (cyclic 10 kN amplitude, up to 260 Hz)

- SincoTec microbending vibration test system (5 N, up to 110 Hz)

Instrumentation

- Various infrared cameras (Micro-Epsilon TIM450/400, Infratec ImageIR® 8300)

- Measuring systems for thermocouples and thermistors (National Instruments, Keysight)

- Uni- and bipolar current sources from Toellner/Kepco for electrical resistance measurement

- Barkhausen noise measurement systems (QASS Optimizer µMagnetic, Stresstech Rollscan)

- Various magnetic field sensors (self-made)

- Eddy Current (Rohmann Elostest M3)

- Videoextensometer (LIMESS Messtechnik)

- Various 2-D DIC systems (LIMESS Messtechnik)

Ambient conditions

- Induction furnace up to 1000 °C (iew TTH3)

- 2- and 3-zone chamber furnaces up to 1200 °C (Severn Thermal Solution)

Tensile testing machines

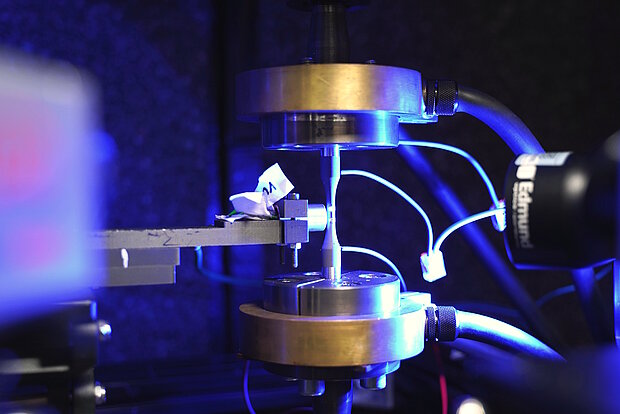

- Micro tensile testing machine (500 N, special design with laser spike system)

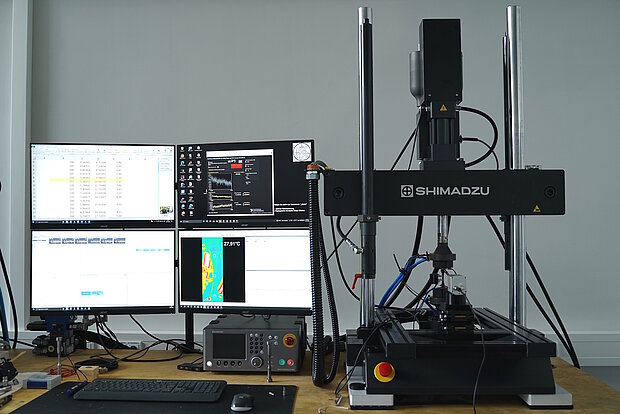

- Shimadzu AGS-10 kN

- Shimadzu AGX-V2 100 kN

Instrumentation

- Various extensometers for RT and HT (Shimadzu Dynastrain, various Sander Messtechnik)

- Various infrared cameras (Micro-Epsilon TIM450/400, Infratec ImageIR® 8300)

- Measuring systems for thermocouples and thermistors (National Instruments, Keysight)

- Uni- and bipolar current sources from Toellner/Kepco for electrical resistance measurement

- Barkhausen noise measurement systems (QASS Optimizer µMagnetic, Stresstech Rollscan)

- Various magnetic field sensors (self-made)

- Eddy Current (Rohmann Elostest M3)

- Videoextensometer (LIMESS Messtechnik)

- Various 2-D DIC systems (LIMESS Messtechnik)

Ambient conditions

- Induction furnace up to 1000 °C (iew TTH3)

- 2- and 3-zone chamber furnaces up to 1200 °C (Severn Thermal Solution)

Further devices and systems

- Rotary bending testing machine Schenck PUP N

- Instrumented micro hardness tester (Helmut Fischer Fischerscope HM 2000)

- Macro hardness tester (Wolpert, Zwick/Roell DuraVision 20 G5)