Separation of surface and volume damage due to HCF/VHCF loading to identify the re-use potential of quenched and tempered steels

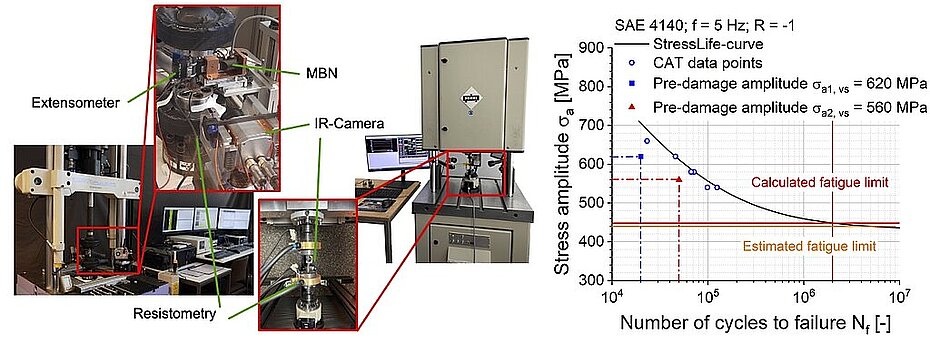

Against the background of the re-use of fatigued components in new machines and plants after reconditioning, a quantitative evaluation of the extent to which the fatigue damage can be divided between surface and volume is to be carried out for the first time within the scope of the project applied for. Therefore, it will be examined to what extent specimens can be manufactured from already loaded and damaged material states and which measurement techniques can be used to characterize the damage state and thus for a physically based evaluation of the further utilization potential. For this purpose, cylindrical test specimens made of the quenched and tempered steel 42CrMo4 are fatigued in the HCF range at 5 Hz until a defined pre-damage is reached and characterized in-situ by means of resistometry, thermometry and magnetic field measurement, followed by scanning electron microscopy.

- +49 631 3724-2448srinivasa.raghuraman(at)hs-kl(dot)de

- Campus Kaiserslautern

- Room H1-2.013

Assistent FB AING, Stellvertretende Fachgebietsleitung

- +49 631 3724-2259fabian.weber(at)hs-kl(dot)de

- Campus Kaiserslautern

- Room H1-2.010.3

Vizepräsident für Forschung und Transfer, Studiengangsleitung "Maschinenbau, Bachelor", Fachbereichsrat AING

- +49 631 3724-2389peter.starke(at)hs-kl(dot)de

- Campus Kaiserslautern

- Room H1-2010.1

Following this characterization, the damaged volume is removed from the specimen, which is polished and then subjected to secondary loading on various test systems at test frequencies of 5, 60, 200 and 1000 Hz. In the HCF range, a direct comparison with the original undamaged specimens can thus be derived. In the VHCF range, possible deviations in fatigue strength can be identified. The scanning electron microscopic characterization of the dislocation arrangement in the surface and volume after initial and secondary loading allows the assignment of potentially different fatigue lives and the related signals of the damage detectors with the microstructure evolution. Assuming that the volume damage leads to a reduction of the fatigue strength or fatigue life during secondary loading, the question further arises whether this condition can be reconditioned, i.e., whether an increase in dislocation density can be relieved by recovery annealing. This is to be verified by means of second loading and SEM investigations, too. Crucial for the component design, which is based here on irreversible surface damage to a depth to be specified, is the formation and propagation of PSGs leading to crack initiation. These processes are to be represented in a mechanism-oriented model to be able to describe the differences between undamaged and pre-damaged specimens. The experimental program includes different specimen geometries, test frequencies and test systems. Therefore, based on previous work of the applicants, a calibration around the frequency effect and the size effect will be performed and finally verified by some selected large-scale specimen experiments.