Quantified evaluation of the frequency influence on the fatigue behavior of unalloyed steels for implementing in resource-efficient fatigue life prediction methods

As a part of the program of the research project, the established fatigue life prediction methods for the HCF regime at frequencies of 5 Hz will be expanded for higher frequencies (up to 260 Hz) and higher cycle numbers (up to 108). The aim is to describe the transition between LCF/HCF and VHCF regime. Extensive mechanical tests are currently being made to extend the LPM at WWHK and are confirmed by detailed characterization of the microstructure by means of various scanning electronic investigations at WPT.

Wissenschaftlicher Mitarbeiter, Teamleitung "Hochfrequenzermüdung“

- +49 631 3724-2461jonas.ziman(at)hs-kl(dot)de

- Campus Kaiserslautern

- Room H3-2.041.2

Assistent FB AING, Stellvertretende Fachgebietsleitung

- +49 631 3724-2259fabian.weber(at)hs-kl(dot)de

- Campus Kaiserslautern

- Room H1-2.010.3

Vizepräsident für Forschung und Transfer, Studiengangsleitung "Maschinenbau, Bachelor", Fachbereichsrat AING

- +49 631 3724-2389peter.starke(at)hs-kl(dot)de

- Campus Kaiserslautern

- Room H1-2010.1

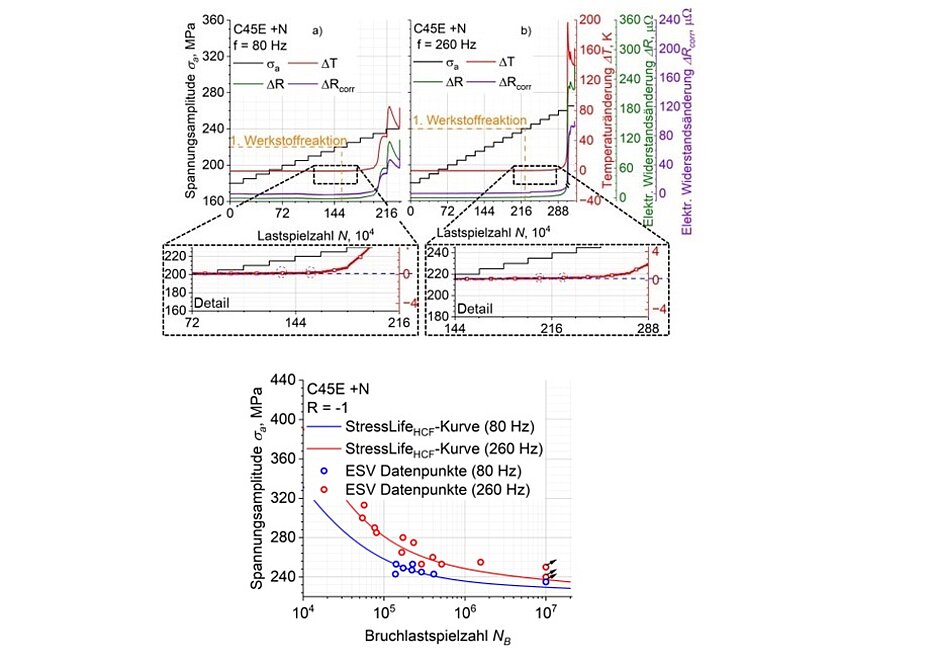

The influence of frequency is clearly recognizable in the cyclic deformation curves of load increase tests (LIT) in the form of a shift of the first material response to higher stress amplitudes (220 MPa for 80 Hz and 240 MPa for 260 Hz). This first material response can also be used to estimate the fatigue strength of the material. The increase in this value with increasing test frequency is due to the fact that the dislocations are increasingly restricted in terms of their mobility, which is why the plastic deformation in the sample volume is reduced or shifted to higher σa values. This is also reflected in the load level of failure of the LIT, which is 240 MPa for 80 Hz and 265 MPa for 260 Hz.

It can be seen that the constant amplitude tests carried out conventionally for validation agree very well with the calculated stresslife-results based on a temperature-corrected electrical resistance. In addition to a significant increase in fatigue life at higher test frequencies, a similar curve progression can be seen in the range of 105 and 106 cycles. Furthermore, the fatigue strength estimated from the curves (σa from which the curves show a horizontal course) agrees with the fatigue strengths estimated from the LIT.