"MibaLeb II“ microstructure-based fatigue life calculation

The overall objective of the joint project is the development of a procedure for the remaining fatigue life assessment of metallic nuclear power plant components that have aged during operation. It is taken into account that the local material properties of components can change due to mechanical, thermal and corrosive loads. In the absence of further information, the effects of such influences are currently covered by safety factors in the component design, which makes the assessment of components and systems against the background of variable operating loads more difficult. More qualified information can enable a more flexible handling of affected components with regard to their service life while maintaining the same level of safety.

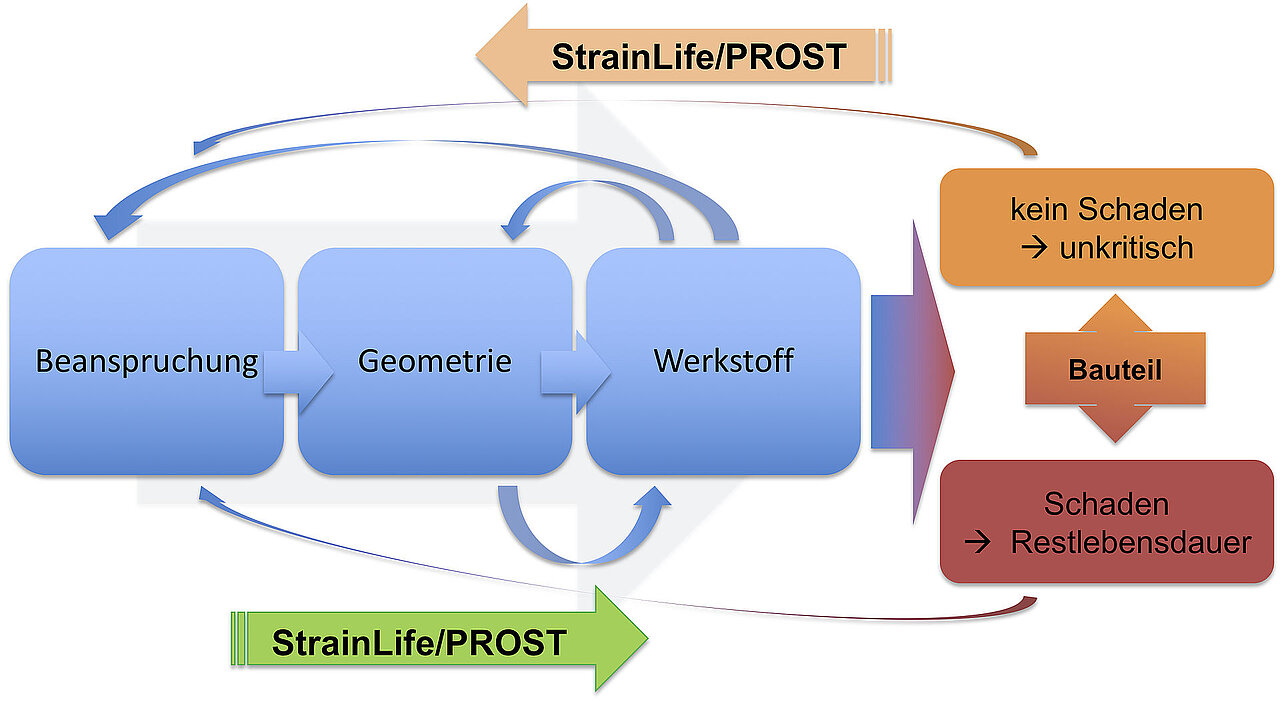

MibaLeb is expected to make a decisive contribution to this. The overall goal of the second project phase is to transfer the results, findings and methods to real and actually loaded materials and components in order to provide reliable information on the integrity and remaining service life of nuclear power plants.The aim of the WWHK subproject is to determine individual ageing states that correspond to the damage states of real components. For this purpose, the damage is to be recorded using NDT methods on real components and transferred to solution-annealed specimens of the same chemical composition by means of thermal and mechanical loads. This should make it possible to carry out accompanying tests in the sense of the StrainLife lifetime calculation method without reducing the structural integrity of the component. A second focus is the further development of the StrainLife method with regard to a multi-parameter approach, in particular to better describe the transition from the LCF to the HCF range. These working points are accompanied by analytical investigations for material and damage characterization.

The subproject is carried out in cooperation with Saarland University, TU Dortmund University, MPA University Stuttgart and the Society for Plant and Reactor Safety Cologne