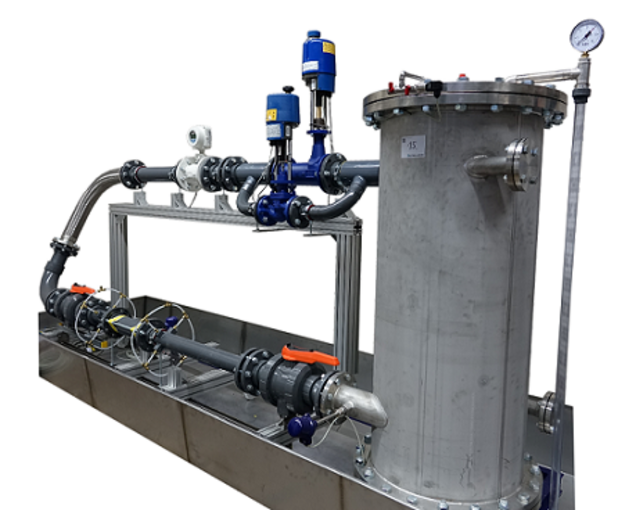

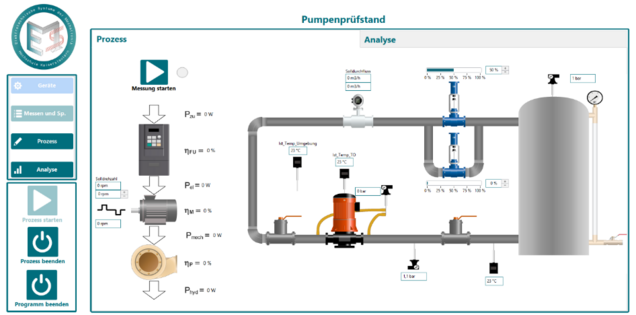

Test stand for centrifugal pumps up to 2 kW:

The test stand for centrifugal pumps up to 2 kW consists of a pressure vessel and pipelines in which the fluid is circulated by the pump unit through the closed hydraulic circuit. Two control valves connected in parallel ensure the throttling of the hydraulic system and thus a variation of the system characteristic curve. To enable the characteristic pump curve for circulating pumps to be recorded, both a differential pressure and a flow sensor are installed. Further measuring sensors include a fluid temperature sensor and an absolute pressure sensor. For the replacement of the pump unit, two ball valves block the circuit, so that only the water in the intermediate pipe has to be drained and thus a complete draining of the water in the entire test bench is not necessary. The control and acquisition of the measuring data is done by a data acquisition module, which is operated via a user interface on a PC. The program used for this purpose was programmed in the working group using the LabVIEW software and enables automated test execution and evaluation.

Equipment:

- Differential pressure sensor

- Flow sensor

- Fluid temperature sensor

- Absolute pressure sensor

- Control valves for throttling

- Connectable vacuum pump