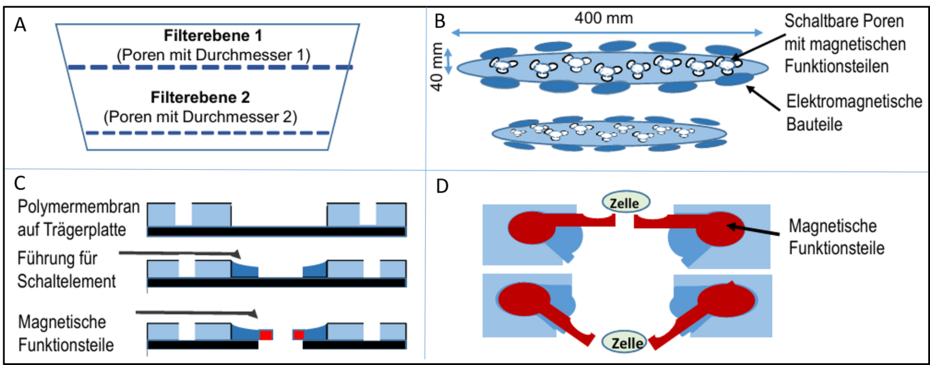

(A) to (D): Schematic gradient filter principle

(A) Cross-section through the filter planes in a column. (B) Top view of two filter planes. These have a narrow shape in order to utilize the maximum possible field strength. (C) Manufacturing diagram for the filter planes (cross-section). A switchable pore is shown in the center. Additional bypass pores are provided on the left and right to allow smaller cells to pass through. (D) Principle of magnetic pore switch (cross-section): At the top, the magnetic functional parts are set so that the pore is not continuous for the larger cells; at the bottom, the cells can pass through.

3D-Life - Research Space for High-Precision 3D Microstructuring for Applications in Life Sciences and Medical Technology

The 3D-Life project focuses on developing innovative three-dimensional microstructures and switchable microfilters for cell filtration for advanced cell research. Two-photon lithography (2PL) is used to produce high-precision, switchable, biocompatible 3D components that enable cultivation in a nature-like environment and gentle handling of cells. This opens up new possibilities for medical diagnostics, cancer, dementia, and immunology research, as well as biotechnological applications.

Research and development work focuses on magnetically switchable microfilter structures with customized designs whose pore sizes can be adjusted in real time. The use of these switchable filter units in a filter column is intended to enable gentle and rapid gradient filtration of blood and immune cells from blood samples. A microchip for disease research is used to detect larger molecules (proteases) produced by immune cells. These are to be separated from the immune cells to enable analysis directly on the chip.

In parallel, a digital technology platform is being developed with multimedia teaching modules and a virtual technology laboratory where students can simulate microtechnical processes. A new 3D Life research college connects these activities and strengthens the training of early-career researchers.

Project manager

Details

BMFTR

Duration01.01.2026 - 31.12.2029