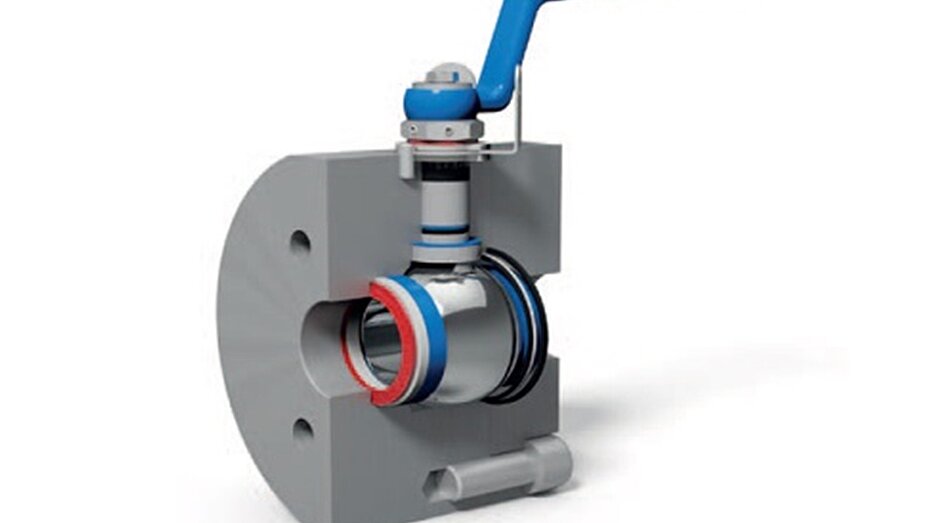

MiDi-PEM: Microstructured metal seals for ball valves using pulsed electrochemical machining

The main aim of this project is to create microstructured curved metallic surfaces for ball valves using Pulsed Electrochemical Machining (PEM). This will allow burr-free microstructures with great design versatility to be manufactured.

The main challenges are the fabrication of the PEM tool and the quality of copying the microstructures of the PEM tool into the workpiece. Different methods and process lines for fabricating the PEM tools as well as process variations for PEM are being investiga-ted. The microstructures are being fabricated using ultraprecision mi¬cromilling or photolithography etching into a metallic substrate. These microstructures are then copied to a polymer substrate and finally into nickel by electroplating. The metallic microstruc¬tured parts obtained in this way are PEM tools. A variety of different microstructure designs are being tested to adapt the surface topography to the functionality of the devices.

Project manager

Contact persons

Details

Federal Ministry for Economic Affairs and Energy

Duration01/2018– 03/2020